MATTEN

Products

- Ultrafiltration (UF) Systems

- Ultrafiltration (UF) Systems

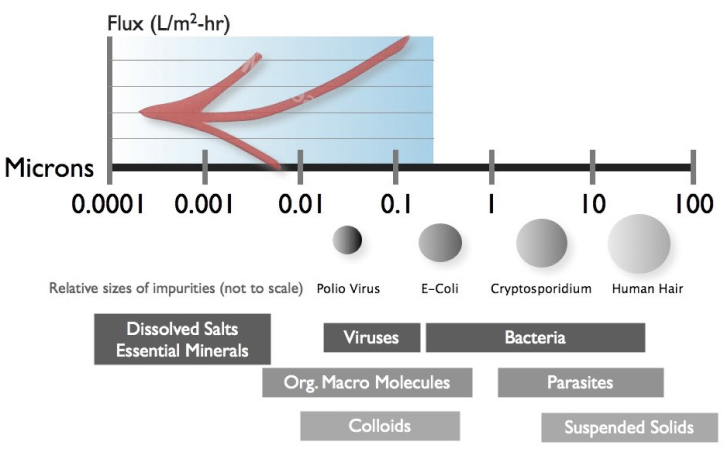

Ultrafiltration membranes have pore sizes in the range of 0.02 – 0.05 microns, which contributes to the production of high-quality water; the pore-size range means that the purification process is characterized by a high removal capability of bacteria, viruses, colloids, and silt. The process, however, does not reject particles smaller than the pores, such as dissolved salts or organics; nor does it reject other species such as true color, taste, and odor.

Advantages of Ultrafiltration:

- Consistency in product water quality.

- Tolerance to feedwater quality fluctuations.

- Physical barrier to viruses and pathogens

- Up to Log 4 reduction for viruses & bacteria.

- Small footprint and less weight

- Less civil/infrastructure required

- Little chemical usage.

- Modular design for easy expansion.

- Highly portable skid based system.

- Robust and simple to operate and maintain

- Fully automated system minimises operator attendance

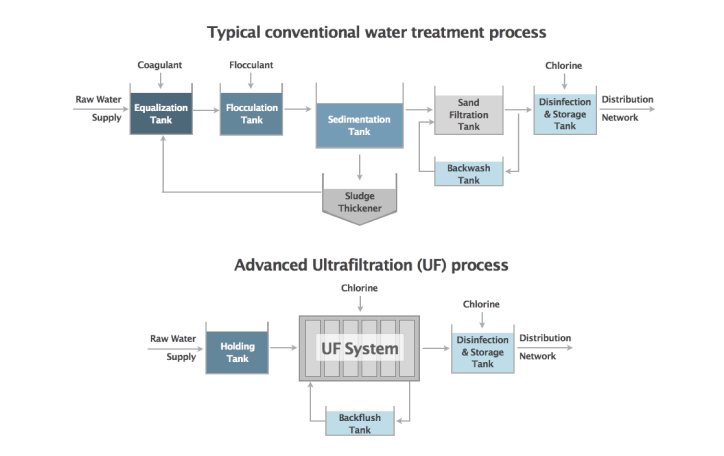

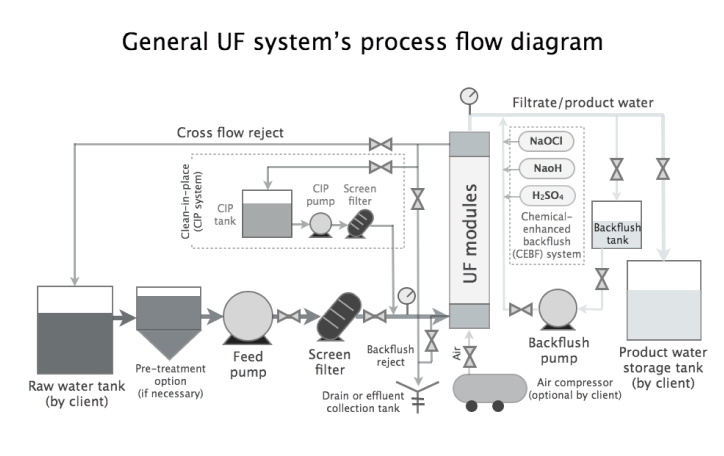

General Ultrafiltration flow diagram

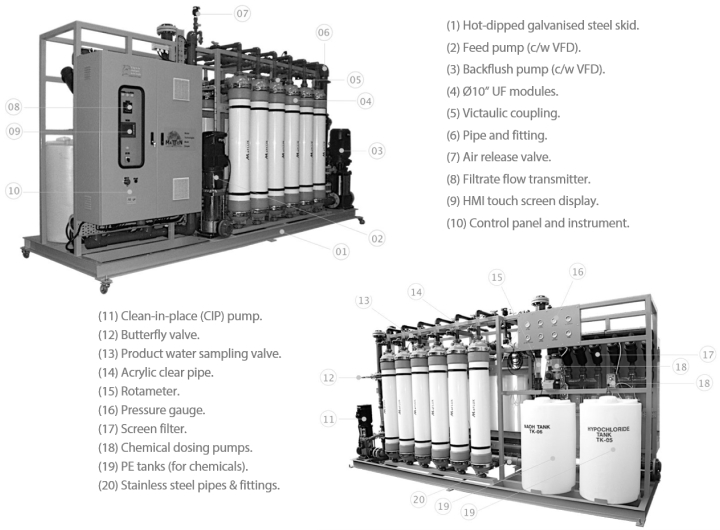

General Ultrafiltration system configuration

One- and two-module systems

Fitted with either Ø10”x48” or Ø10”x60” modules, our plug-and-play standard UF systems start with one- and two-module systems. Subject to feed water qualities, they are capable of producing 2 m3/hr to 6 m3/hr of filtrate respectively. These systems are suitable for small house-hold and commercial applications.

Fully integrated standard systems

Beginning with careful selection of membrane and modules, completing with all essential equipment, parts and components for a truly standard, modular and packaged UF system. All on the same skid for a truly plug-and-play water purification plant. Selection of all other quality items integral to the optimal performance of the membrane and modules is as important. Be they skid’s materials and finishings, pumps, valves, pipes and fittings, control panel and instrument, cables and wiring works, there is no compromise on selecting the best available for a fail-proof packaged UF system.

Our modular UF skids are made for installation at the project sites requiring large flux rates. They are designed and configured for ease of shipments with 20’/40’ containers. Multiple skids can be installed with hassle-free inter-skid connections to be carried at project sites.

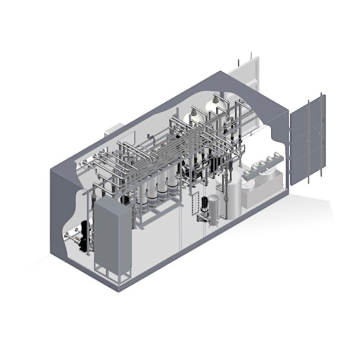

Containerised Ultrafiltration system

Integrating all the UF modules and other integral equipment, parts and components into a constrained space of a container to produce the greatest flux possible, and still making sure that the space is optimised for service and maintenance, is harder than you think. It requires not only versatile expertise in UF technologies and established engineering experiences, it also needs out-of-the-box creativity and innovative strife. We are capable of doing just that – compact containerised UF systems that take raw water in from one end, and churn out filtrate of your desired qualities from the other.

Features

Standard features

- UF modules (PVDF hollow fiber with PVC housing)

- backwash pump

- Chemical enhanced backwash system

- Membrane CIP system

- 100 mesh flushable screen/disc filter

- Schedule 80 PVC piping

- Electrically actuated valves

- Flow meter

- Differential pressure switch

- Liquid filled pressure gauges (field-mount)

- Microprocessor control panel

- Motor starters

- IP54 powder coated steel control panel enclosure

Available options

- Online turbidity monitor

- Stainless steel multistage feed pump

- Stainless steel piping

- Feed/backwash pump VFD

- Feed/backwash chlorination system

- Pressure transmitter (feed/filtrate/crossflow)

air compressor for air scouring backwash - Filtrate (backwash) tank (HDPE)

- PLC + HMI

Applications

- Drinking water treatment

- RO pretreatment

- Grey water treatment

- Water Recycling And Reuse

- For more information, please download our UF catalog