MATTEN

Solutions

- Water Treatment Solutions

- Seawater Desalination Solutions

- Wastewater Treatment Solutions

- Wastewater Recycle & Reuse Solutions

- Disinfection Solutions

- Advanced Oxidation Solutions

- Digital Solutions

Seawater Desalination Solutions

Our “blue marble” is a water planet, with over 70 percent of the earth’s surface covered by water. But, the problem is that this water isn’t drinkable because it is saturated with salt. To solve that problem, more and more countries are turning to the process of desalination to produce clean drinking water, and water for agriculture and industrial uses.

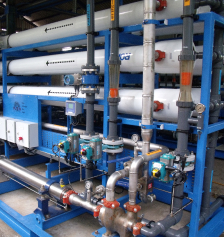

Among several desalination techniques, Seawater Reverse Osmosis (SWRO) has emerged as the preferred method. Compared to other processes, SWRO has proved to be a highly efficient way of producing clean, uncontaminated freshwater from seawater. The technology for SWRO is also simple and safe; high-pressure pumps force seawater through desalination membranes to create multi-purpose freshwater, removing over 99 percent of dissolved salts and impurities in the process.

Due to its high energy efficiency and reliability, Sea Water Reverse Osmosis (SWRO) is one of the most sustainable and cost effective solutions for converting seawater to potable fresh water. At the same time, SWRO technology undergoes rapid development to improve energy efficiency and support large-scale freshwater production.

Features and benefits

- Extremely low energy consumption

- Ultra-low maintenance costs

- Simple to operate

- Minimal service and long service intervals

- Small footprint but effective, compact and light in weight

Our offerings:

- Modular SWRO system

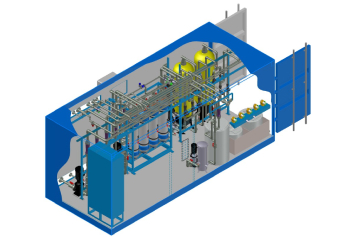

- Containerized SWRO plant

- Large desalination plant design-and-build

Our SWRO systems and plants have been used in a wide range of applications – oil rigs, gas platforms, oil service barges, ports and jetties, resorts, island communities, power plants, refineries, military outposts and more.

Featured SWRO applications:

City water polishing for direct potability usage in hotels

Safe drinking water direct from tap

Seated in Singapore, we are very lucky to enjoy the safe drinking water directly from the tap. However, this is not possible for other regional countries, where public water works and pipings are sometimes not in good condition.

MATTEN has worked together with a 5-star hotel operator in Kuala Lumpur, Malaysia, to develop a city water purification system for all the guest houses in the hotel. With our carefully considered Ultrafiltration system, and continuous UV reticulation, the drinking water supply to the hotel is always kept safe, making this one of the very few hotels in Malaysia that offers hassy free drinking water directly from the tap.

From borehole to potable water for remote mining camp.

Australian-Mining-Standards-compliant

Containerized UF systems for the mining industries.

Mining more. Minding less.

In the mining industries, the miners would want to mine most and mind the utility facilities least. Water treatment and supply infrastructures and plants, among others, shall be relatively hassle-free on a day-to-day basis. However far or remotely located the mining sites and men-camp’s are from the urban areas. Over the years, we have learned and built user-friendly and hassle-free UF systems that meet the Australian Mining Standards to purify natural water for potable use by the mining operators. Whether they are open skid-based or containerised systems, we have supplied to established and reputable mining companies in the region, especially in Australia.

MATTEN together with our distributor in Australia designed and built a turn-key potable water system for a 200-man mining camp at Condabri mine, Queensland. The 20ft containerized UF system with continuous sterilization produces 60m3/day of good quality potable water in compliance with Australian Drinking Water Guideline. The plant was equipped with the GSM system for remote alarm and monitoring and minimum attention required for daily operation.

Removal of traces of uranium.

Heavy metals are present in ground water and are usually Nickel, Lead, Cadmium, uranium, etc. Though these metals usually present in cationic form and very low concentration, heavy metals are highly toxic and must be removed to very low levels in drinking water supplies.

The common methods for removing metals from water like ion exchange, reverse osmosis. However, RO is not a very cost-efficient method for low salinity water. Consider this, MATTEN with our partner in West Australia designed and built a 7.7 m3/hr containerized selective ion exchange system for specific uranium removal. Given the low level of uranium the ion exchange system can be used for months before regeneration by acid and caustic soda. Considering the rather remote rural area of Pilbara community in Western Australia, the containerised system was designed to be fully automatic and to be monitored remotely by the local government agency. The signal connectivity was through a satellite dish mounted on top of our container.

Industrial process water applications where much more stringent specification applies:

Process water for refinery’s industrial use

Two trains of SWRO and BWRO modular skids were installed and commissioned for a large international oil and gas company’s refinery located on-shore in Indonesia. The SWRO is designed with a capacity of 1200 m3/day. Apart from the operators’ consumption,30% of the desalinated water was further polished by BWRO systems for the refinery’s day-to-day process applications consumption.

Potable water for oil rig’s operators

certified SWRO water maker

Fit for oil and gas industry.

Surely great for many more.

Our modular SWRO water maker has been popular among the major oil drilling companies for years. We have pre-designed and built compact SWRO systems that meet the most stringent and demanding engineering and industrial standards worldwide. Our compact water maker is approved by American Bureau of Shipping (ABS) for off-shore installation and applications.

Pre-engineered designs of our systems saved our teams a lot of time for production. Our system was flexible for demolition on the oil rig’s open deck, and for re-assembly within the constrained space on the oil-rig. Comprehensive Factory Acceptance Tests (FATs) have been done at our factory with our experts team, so that the system could be commissioned and handover within a few days after installation, largely shortening the project execution time at site.

Containerised SWRO system for remote island

Like a magic box.

Seawater from one end.

Potable water from the other.

Our containerised SWRO system met the military client’s stringent requirements, and saved the customer hassles of building any shelter structures at the resource-limited base. Completely plug and play, the system was installed and commissioned within a week.

Potable water package used in desert

Explosion-proof designed for oil and gas application

Special-painted with desert-proof protection

Quenching thirst with everything integrated on 1 skid

Our all-in-one potable water package met the most stringent Japanese oil and gas requirements. Everything was installed on a skid allowed on a 40ft flat rack container, including sand filters as pre-treatment, backwash water tank and control panel.

Drinking water for a remote island.

Seawater RO (SWRO) systems, pre-treatment of feed-water prior to salinity removal is of high importance to ensure stable and reliable plant operation; biological fouling due to high organics in seawater are common problems in RO plants, which require design experience and application knowhow. Beside conventional multi media filtration (MMF), an advanced method using ultrafiltration membrane is used for this project.

Our skid-based standard and modular UF and SWRO systems made the shipment and transportation to an exceptionally remote fishing island of Indonesia so easy. With little skilled labour available on the island, our systems were still installed on-site rather hassle-free. The systems were fast commissioned to much of the delight of the island’s inhabitants.

Download our catalog and project references.