MATTEN

Solutions

- Water Treatment Solutions

- Seawater Desalination Solutions

- Wastewater Treatment Solutions

- Wastewater Recycle & Reuse Solutions

- Disinfection Solutions

- Advanced Oxidation Solutions

- Digital Solutions

Water Treatment Solutions

At MATTEN, we strive to make water technologies simple for sustainable water resources, by transforming complex technologies into simple and straightforward integrated systems. Our vision is to make each of our systems your best investment, by selecting the most suitable technologies, with our experiences and expertise.

From conventional to state-of-the art technologies, we provide water treatment solutions that can reliably deliver safe drinking water to municipalities and government entities, high-quality ingredient water for food and beverage manufacturing, pure and ultrapure water for use in the process industries such as power plant, electronics and semiconductor, pharmaceutical, refineries and petrochemical industries.

Our expertise encompasses the following treatment processes, and more:

- Coagulation, flocculation and sedimentation

- Dissolved air flotation

- Media filtration and adsorption

- Ceramic membrane filtration

- Ultrafiltration

- Reverse Osmosis

- Membrane processes

- Ion Exchange and CEDI

Featured water treatment for municipal applications,

where safe drinking water is required:

River to taps.

Natural water to potable water.

Consistent water quality. Everyday.

Drinking water must be free of suspended solids, microorganisms and toxic chemicals. We have a comprehensive range of standard and modular UF systems pre- designed and pre-engineered to purify many types of natural waters to meet WHO’s (World Health Organisation) standards for potable use. Whether it is from underground, wells, lakes, rivers, reservoirs, rain collections, our UF systems are designed for up to Log-6 removals of bacteria and viruses, and a whole host of other impurities and contaminants. They are well suitable for municipal water supply, or for business operations such as mines’ camps, industrial and residential townships, resorts, hotels, theme parks etc.

MATTEN together with our partners in Indonesia designed and built a turn-key surface water ultrafiltration system in Balikpanpan, Indonesia. The system has been installed, commissioned, supplying safe drinking water to a village of 4000 population, since 2011. The plant was designed with simple yet comprehensive automation controls that even the villagers could learn how to operate and maintain the system after handover.

City water polishing for direct potability usage in hotels

Safe drinking water direct from tap

Seated in Singapore, we are very lucky to enjoy the safe drinking water directly from the tap. However, this is not possible for other regional countries, where public water works and pipings are sometimes not in good condition.

MATTEN has worked together with a 5-star hotel operator in Kuala Lumpur, Malaysia, to develop a city water purification system for all the guest houses in the hotel. With our carefully considered Ultrafiltration system, and continuous UV reticulation, the drinking water supply to the hotel is always kept safe, making this one of the very few hotels in Malaysia that offers hassy free drinking water directly from the tap.

From borehole to potable water for remote mining camp.

Australian-Mining-Standards-compliant

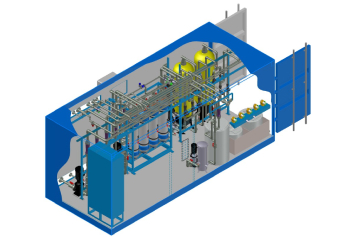

Containerized UF systems for the mining industries.

Mining more. Minding less.

In the mining industries, the miners would want to mine most and mind the utility facilities least. Water treatment and supply infrastructures and plants, among others, shall be relatively hassle-free on a day-to-day basis. However far or remotely located the mining sites and men-camp’s are from the urban areas. Over the years, we have learned and built user-friendly and hassle-free UF systems that meet the Australian Mining Standards to purify natural water for potable use by the mining operators. Whether they are open skid-based or containerised systems, we have supplied to established and reputable mining companies in the region, especially in Australia.

MATTEN together with our distributor in Australia designed and built a turn-key potable water system for a 200-man mining camp at Condabri mine, Queensland. The 20ft containerized UF system with continuous sterilization produces 60m3/day of good quality potable water in compliance with Australian Drinking Water Guideline. The plant was equipped with the GSM system for remote alarm and monitoring and minimum attention required for daily operation.

Removal of traces of uranium.

Heavy metals are present in ground water and are usually Nickel, Lead, Cadmium, uranium, etc. Though these metals usually present in cationic form and very low concentration, heavy metals are highly toxic and must be removed to very low levels in drinking water supplies.

The common methods for removing metals from water like ion exchange, reverse osmosis. However, RO is not a very cost-efficient method for low salinity water. Consider this, MATTEN with our partner in West Australia designed and built a 7.7 m3/hr containerized selective ion exchange system for specific uranium removal. Given the low level of uranium the ion exchange system can be used for months before regeneration by acid and caustic soda. Considering the rather remote rural area of Pilbara community in Western Australia, the containerised system was designed to be fully automatic and to be monitored remotely by the local government agency. The signal connectivity was through a satellite dish mounted on top of our container.

Industrial process water applications where much more stringent specification applies:

Sanitary compliant integrated membrane system for F&B ingredient water.

Australian-Mining-Standards-compliant

Containerized UF systems for the mining industries.

Mining more. Minding less.

In the mining industries, the miners would want to mine most and mind the utility facilities least. Water treatment and supply infrastructures and plants, among others, shall be relatively hassle-free on a day-to-day basis. However far or remotely located the mining sites and men-camp’s are from the urban areas. Over the years, we have learned and built user-friendly and hassle-free UF systems that meet the Australian Mining Standards to purify natural water for potable use by the mining operators. Whether they are open skid-based or containerised systems, we have supplied to established and reputable mining companies in the region, especially in Australia.

MATTEN together with our distributor in Australia designed and built a turn-key potable water system for a 200-man mining camp at Condabri mine, Queensland. The 20ft containerized UF system with continuous sterilization produces 60m3/day of good quality potable water in compliance with Australian Drinking Water Guideline. The plant was equipped with the GSM system for remote alarm and monitoring and minimum attention required for daily operation

Containerized Demineralized Water Plant for the production of water-based paints and varnishes

With UF system as the pre-treatment option, we designed and supplied a fully containerised RO system (9.5 m3/hr) to produce process water for Dulux (Australia)’s production’s needs.

Fully tested at our factory through our vigorous FAT’s procedures, our containerised system was connected pipe-in-pipe-out and wired without hassle at the client’s factory site. The system was made to meet AS3000 requirements.

Ultra-pure water for aviation processing.

The project involved supply of a 5 m3/hr SDI system to produce pure water for Singapore Aerospace Engineer Services Pte Ltd’s (SAEPL) processing of aviation parts and components. In this project, we also supplied physio-chemical wastewater treatment plant to treat the plant’s effluent to meet the discharge standards of Singapore’s national environmental agency. The project was executed on an EPC basis.

Demineralized water for the refinery.

We supplied a standard and modular 250 m3/day demineralization system system to Oil & Gas Development Co. (Pakistan) Ltd for its oil and gas refinery’s operations. As a well established company, our teams went through a very stringent tendering and clarification process to secure this project, which was well delivered and on schedule for the end-user’s project implementation.

Demineralized water for the refinery.

We supplied a standard and modular 250 m3/day demineralization system system to Oil & Gas Development Co. (Pakistan) Ltd for its oil and gas refinery’s operations. As a well established company, our teams went through a very stringent tendering and clarification process to secure this project, which was well delivered and on schedule for the end-user’s project implementation.

Ultrapure water for pharmaceutical applications

With MMF and activated carbon pre-treatment systems, our -pass MH-RO with mixed bed polishing system was used to produce 1.3m3/hr of process water for use by a pharmaceutical customer in Singapore.

Small system as it was, it was more than capable of producing process water that met the stringent ultra pure grade water parameters.

Download our catalog and project references.